Post-processing 3D printed parts often involves hazardous dust, reactive metals, and explosion risks – The standard of safety during manual postprocessing is of upmost importance.

Traditional protective gear alone isn’t enough – Protective suits are often only worn during individual working stages and are of no help against the risk of deflagration. Moreover, the working areas are not protected from invisible airborne dusts, which are usually underestimated.

The ENESKA Postprocess System provides a fully enclosed, explosion-proof workstation that keeps operators safe while delivering precision finishing results.

Expert Advice: Post-Processing 3D Printed Parts Safely and Effectively

In this blog we delve into workplace safety and the post processing of 3d printed [...]

Mar

Particular caution is required when processing reactive materials. In this case, it is not only the dusts that can ignite through friction; the material is also highly flammable and therefore carries higher risks of explosion and deflagration. A special moisture extractor with 5-fold filtration and explosion protection according to ATEX standard guarantees safe work. An integrated liquid bath binds the reactive particles which are thus unable to develop their explosive effect.

Titanium or aluminium are the common materials that most users recognised as reactive, but many alloys also have references to minimum ignition energy in their data sheets.

Key Features

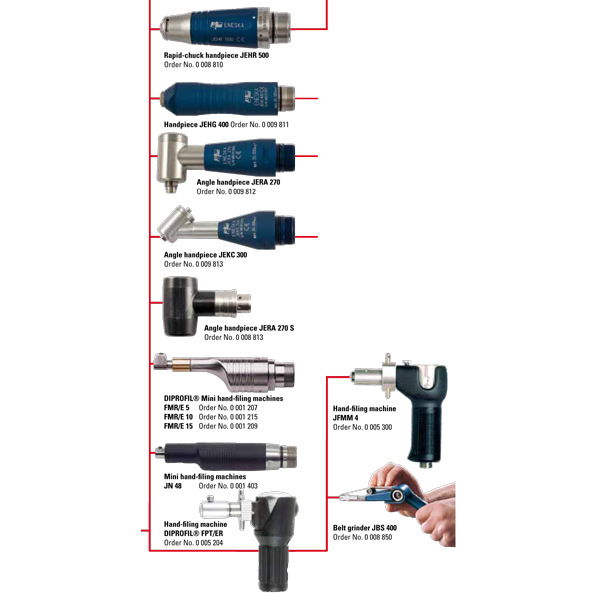

With integrated control units, operators can remove supports, deburr, grind, and polish components efficiently—using micromotors running up to 60,000 rpm. A 5-fold filtration system, wet scrubber option, and ATEX-certified safety features protect against both health hazards and explosive deflagrations from reactive materials like titanium and aluminium.

The adjustable working height and ergonomic design ensure operator comfort, while the FSX fine dust measuring system guarantees maximum dust safety compliance.

Whether you need to improve safety standards, handle reactive materials, or boost post-processing efficiency, ENESKA delivers reliable performance and compliance for modern 3D printing environments.

-

Complete Safety Enclosure: Protects against harmful dust and explosive risks.

-

5-Stage Filtration System: HEPA H13 filters with 99.995% dust retention efficiency.

-

Explosion-Protected Design: ATEX certified for reactive materials like titanium & aluminium.

-

Versatile Workspace: Integrated controls for grinding, polishing, deburring & support removal.

-

Ergonomic Height Adjustment: Work comfortably while standing or sitting.

-

High Extraction Capacity: 350 m³/h airflow with side-channel blower for tight corners.

-

Contactless Post-Processing: Minimises operator exposure to dust and fumes.

-

Multi-Tool Integration: Up to three micromotors & two pneumatic tools connected at once.

Watch a video summary from the manufacturer.

Technical Specifications

| Feature | Specification |

|---|---|

| Working Chamber Dimensions | 930 x 790 x 250–600 mm |

| Device Dimensions | 1300 x 1500 x 1790 mm |

| Lighting | 5,000K / 3,300 lm, dimmable |

| Supply Voltage | 400 V / 16 A |

| Weight | 600 kg |

| Extraction Capacity | 350 m³/h, 5-stage filtration |

| Explosion Protection | ATEX certified, Zone 22 compliant |

| Material Compatibility | Aluminium, Titanium, and various alloys |

| Tool Integration | 3 micromotors, 2 pneumatic devices |

| Fine Dust Safety | FSX automatic measuring system |

For more information Read this PDF.

Ready to upgrade your 3D printing post-processing?

Contact Moleroda today for prices, expert advice, and custom configurations.